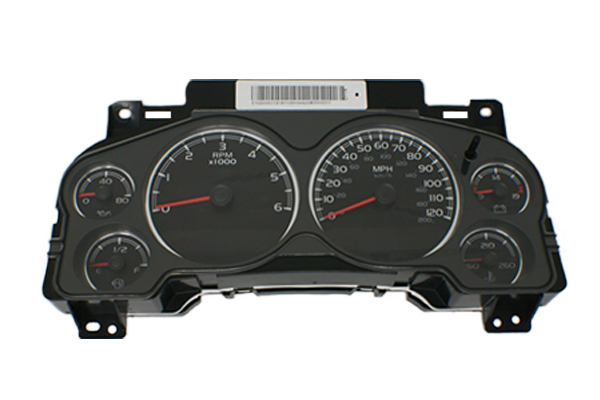

Effective Tahoe Instrument Cluster Repair: Obtain Your Gauges Working Again

Discover Top Techniques for Reliable Vehicle Tool Cluster Repair Service and Maintenance

In the world of auto upkeep, the complex system of a tool collection plays an important function in supplying drivers with essential info about their car's efficiency. When encountered with issues associated with this vital element, having an extensive understanding of effective repair and maintenance methods is paramount. From identifying typical collection malfunctions to utilizing specialized devices for accuracy repairs, a methodical approach can ensure optimal functionality and longevity of this crucial dashboard function. Keep tuned to reveal the leading approaches that can enhance the procedure of auto instrument collection repair work and maintenance, eventually improving your driving experience and car performance.

Usual Instrument Collection Issues

Some usual problems might occur with lorry instrument clusters, influencing their performance and accuracy. This problem can be caused by a malfunctioning gas degree sensor or a defective scale collection. These issues can impede the vehicle driver's ability to check necessary lorry info, stressing the relevance of timely tool cluster fixing and maintenance to ensure optimal performance and accuracy while driving. tahoe instrument cluster repair.

Important Tools for Repair Work

When addressing typical tool cluster problems such as malfunctioning speedometers, less competent fuel gauges, or dark dashboard lights, having the necessary tools for repair service is critical in guaranteeing accurate and efficient diagnostics and upkeep. Amongst the primary devices needed for car instrument collection repair are a digital multimeter for testing voltage and resistance levels, a welding torch for dealing with loosened connections or damaged components, and a collection of screwdrivers for taking apart the collection. Additionally, specialized tools like cluster removal hooks might be essential for safely separating the collection from the dashboard.

Analysis Methods for Fixing

Using sophisticated diagnostic methods is necessary in effectively troubleshooting concerns within car tool clusters to identify and address underlying issues precisely. By following organized diagnostic treatments and interpreting diagnostic results properly, technicians can streamline the troubleshooting procedure and make certain the proper performance of the tool cluster. A complete analysis strategy not only saves time but also promotes accuracy in identifying and fixing instrument cluster problems immediately.

Cleansing and Maintenance Tips

Software Application Updates and Calibration

Calibration is one more vital element of preserving your automobile instrument cluster. This procedure entails changing the setups and parameters within the software to make certain that the displayed details, such as speed, gas level, and temperature, is exact and reputable. Correct calibration not only improves the individual experience however likewise adds to safety and security when driving by offering chauffeurs with exact and dependable data.

To make certain that your vehicle tool cluster operates optimally, it is suggested to comply with the manufacturer's standards relating to software updates and calibration intervals. By remaining proactive in these locations, you can optimize the efficiency and lifespan of your instrument collection.

Conclusion

In conclusion, effective car instrument cluster fixing and upkeep call for a detailed understanding of usual concerns, essential tools, diagnostic strategies, cleaning techniques, and software application updates. By utilizing these strategies, specialists can efficiently deal with and repair tool collection issues, making certain accurate and dependable performance of the automobile's dashboard display screen. Routine upkeep and calibration are essential to stop future issues and making certain the proper performance of the instrument cluster.

When resolving common instrument cluster problems such as malfunctioning speedometers, unresponsive gas evaluates, or dark control panel lights, having the important tools for repair is critical in making certain effective and accurate view it now diagnostics and maintenance. Among the main devices required for auto tool cluster repair are a digital multimeter for screening voltage and resistance levels, a soldering iron for fixing loosened connections or damaged components, and a collection of screwdrivers for dismantling the cluster. Furthermore, specialized tools like collection elimination hooks might be required for securely removing the cluster from the control panel.

In final thought, efficient car instrument collection fixing and upkeep require an extensive understanding of usual problems, vital tools, analysis methods, cleansing methods, and software application updates. Regular upkeep and calibration are essential to preventing future issues and guaranteeing the appropriate performance of the instrument cluster.